Pin Out:

|

PIN |

DESCRIPTION |

|

VCC |

Power ( + Terminal ) |

|

GND /VSS |

Ground (- Terminal) |

|

U/D |

Up/Down |

|

INC |

Increment |

|

CS |

Chip select |

|

VH/RH |

High potential

terminal |

|

VW/RW |

Optimum potential |

|

VL/RL |

Low potential |

Features

Ø Solid-state potentiometer

Ø 99 resistive elements.

Ø Three-wire Serial interface

Ø 100 wiper tap points

Ø Low power CMOS technology

Ø Standby current (750uA)

Ø Active current (3A-max)

Specifications

Ø Supply voltage: 3V-5V

Ø Chip: X9C103S

Ø Dimensions : 28 x 14 x 4 (LxWxH) mm.

Ø 10K span potentiometer.

Ø Potentiometer center tap between 0-10k slide in total 100 (potentiometer wiper typical impedance 40 ohms)

Ø VL and VH Digital Potentiometer sliding rheostat port corresponding to the low-end and high-end, allowing the input voltage range -5V to + 5V.

Standard Resistance Value:

Ø X9C102 = 1kW

Ø X9C103 = 10kW

Ø X9C503 = 50kW

Ø X9C104 = 100kW

How to use X9C103S-DIGIPOT

Vcc, Gnd are power supply pins connected to the dc power source (required voltage), U/D, INC, CS are input pins with the active LOW state, remaining three pins VH/RH, VW/RW, VL/RL are output pins, so this output terminal acts just like a present(Potentiometer) three terminals.

Principles of operation

Instructions and programming

The INC,

U/D and CS inputs control the development of the wiper along with the resistor

exhibit. With CS set LOW, the gadget is chosen and empowered to react to the

U/D and INC inputs. HIGH to LOW changes on INC will addition or decrement

(contingent upon the condition of the U/D information) a 7-piece counter.

The yield of this counter is

decoded to choose one of 100 wiper positions along with the resistive cluster. The

estimation of the counter is put away in non-unstable memory at whatever point

CS changes HIGH while the INC input is additionally HIGH. The framework may

choose the X9Cxxx, move the wiper and deselect the gadget without putting away

the most recent wiper position in non-unstable memory.

After the wiper development is preceded

as recently depicted and once the new position is reached, the framework should

keep INC LOW while taking CS HIGH. The new wiper position will be kept up until

changed by the framework or until a shut down/upcycle reviewed the recently

put away information. This technique permits the framework to consistently

control up to a pre-set worth put away in non-unpredictable memory; at that point

during framework activity, minor changes could be made. The changes may be

founded on client inclination, i.e.: framework boundary changes because of

temperature float, and so forth The territory of U/D might be changed while CS

stays LOW. This permits the host framework to empower the gadget and afterward

move the wiper all over until the appropriate trim is achieved.

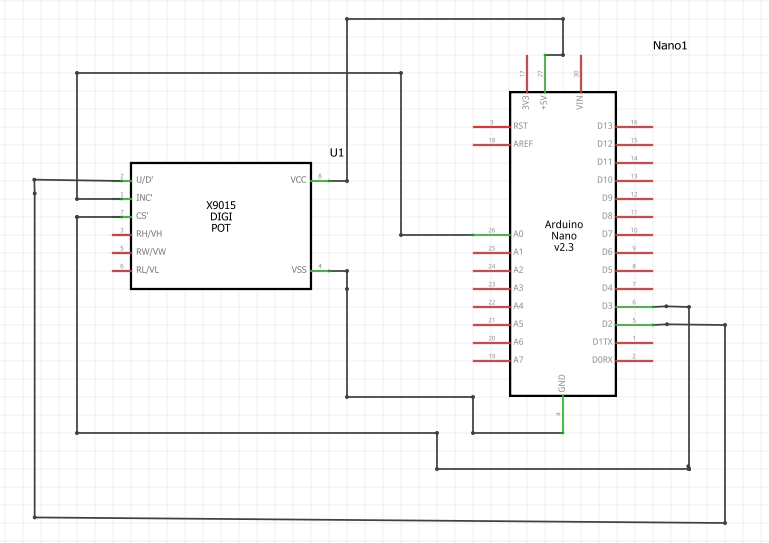

Arduino with X9C103S-DIGIPOT

Schematic of DIGI-POT

DATASHEET

Applications

- sensors trimming

- calibration of readings

- instrumentation-gain or offset adjustment

- optical networks

- audio controllers

0 Comments